Next time you visit

a yarn shop, take a good look at the

wool yarns. Besides color and weight,

you'll notice another big difference

among them -- the way the yarns are

plied, the way the individual plies

of wool are twisted around each other

to make the final yarn. There are

four main ways of plying that are

done nowadays -- conventional, single,

cabled and multi-strand - and these

can cause some noticeable differences

in the way that stockinette stitch

will appear in your knitting.

When you use these

four kinds of yarns, you likely don't

think about their construction in

such detail. Isn't all that matters

that your knitting looks fine and

you've gotten the correct gauge?

Maybe not. The way

a yarn is plied can cause it to lie

differently after it's knit into a

fabric. This especially shows up in

stockinette stitches, where you see

the two halves of the V that form

each stitch on the right side of the

piece.

Have a look at the

following photos to see what's going

on. (Note -- the photos are been enlarged

to show more detail).

Conventionally

Plied yarns

|

These

are the workhorses of wool yarns,

and have been spun for decades.

Most often you'll see four plies

of yarn twisted around each

other, like in the Debbie Bliss

Merino Aran shown at left.

Each ply is

called a 'single' because it

can't be broken down into more

strands; if you try pulling

one of the singles apart, you

get loose fiber. You can also

find yarns of only two or three

plies spun like this.

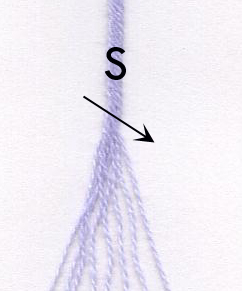

The final

yarn is twisted in the 'S' direction.

What this means is if you overlay

the letter 'S' over the yarn

strand, you can see that the

middle bar of the letter mimics

the direction of the final twist.

This direction is also pointed

out by the arrow. |

|

Stockinette

stitch with 4-ply yarn

The two halves

of each knit stitch are slanted

at nearly the same angle, and

each side of the stitch is almost

the same width. |

| Singles Yarns |

|

|

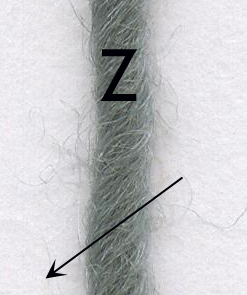

Sometimes

a yarn consists of one big single.

A good example is Brown Sheep's

Lamb's Pride Worsted, in which

many fibers are twisted around

each other to make one big ply.

Untwist the yarn and it's easy

to see all the loose fibers. The

only twist in the yarn is in the

'Z' direction. |

|

When

knitted up, it looks as if the

left side of each stitch is

twice as wide as the right side

and tilted at a different angle.

The right-side stitches appear

to be forming one continuous

vertical column.

There's nothing happening wrong

with the knitting; this is simply

how the yarn wants to lie, so

there will be no stress or bias

in the fabric. |

| Cabled yarns |

|

|

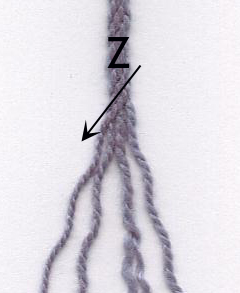

You

can take conventionally S-plied

yarns, and make a thicker yarn

out of them by doing a one more

twisting in the Z direction.

This is how a cabled yarn is

made; the final yarn has the

look of a cabled cord. All this

twisting results in a firmly

spun yarn. Adrianne Vittadini's

'Trina' is an example of this.

The final

yarn, which has its twist in

the Z direction, consists of

4 strands. Each strand is made

from 2 singles twisted around

each other. In the photo, the

third strand has been untwisted,

to show the loose fibers from

the two singles. |

|

In the final yarn, you can

see some of the little twists

from each of the four strands,

which gives this yarn its distinctive

'cabled' look. And with a cabled

yarn, stockinette stitch looks

rather distinctive too. Both

halves of each knit stitch are

equal in width, and tilted to

the same degree.

However, you can make out the

little twistings within each

of the four strands, which gives

the fabric a slightly textured

look. |

| Multi-strand

Yarns |

|

|

In the past

10 years or so, these yarns

have become more and more available.

They are called a number of

different names -- multi-strand,

multiple stranded, multi-ply,

many-plied, Merino S twisted,

and S-on-S multi-strand. Occasionally

they are called 'cabled' yarns,

but that's confusing with the

real cabled yarns shown above.

Plus, these multi-strand yarns

are made in a completely different

way.

Aurora 8 yarn

from Karabella is a multi-strand

yarn. The final yarn is made

from 8 thin 2-ply strands; hence

the number '8' in the name.

The 8 strands are twisted around

each other again in the S direction.

It may appear

that the final yarn is tightly

twisted, but it's not. It's

just the way the eight thin

strands want to lie next to

each other. If you untwist the

yarn, you can see that it's

not overspun. In fact, the yarn

feels quite soft and flexible,

and has good elasticity.

|

|

When

knitted up, these yarns have their

own unique look. The right side

of each stitch is nearly twice

as wide as the left side, and

tilted at a different angle. It

almost looks like the left sides

of the stitches are forming one

continuous vertical column. |

Why would a mill

go to the trouble of spinning thin

little 2-ply strands, if they are

just going to twist a bunch of them

together to make a thicker hand knitting

yarn? At first glance, it seems like

a lot of effort to go through.

Most of these yarns

are spun in Italy, and that's the

big reason why this multi-strand business

is done. A spinning mill can make

the thin 2-ply yarns for commercial

knitwear. The spinning mill can also

make hand knitting products by simply

twisting several of these 2-ply yarns

around each other, then skeining off

these thicker yarns into 50- or 100-gram

balls.

A spinning mill

covers a lot of bases by doing things

this way. First, the mill spins and

dyes the thin 2-ply yarns for commercial

knitwear. Then the mill can take four,

six, eight or ten of the thin 2-ply

yarns, and twist them together to

make, respectively, fingering weight,

DK weight, heavy worsted and bulky

weight yarns.

Not a bad way to

keep commercial and hand knitting

customers happy and well fed.

The bottom line

in all this is that there's nothing

wrong with your knitting, and nothing

wrong with the yarns. They aren't

poorly made, over-twisted or under-twisted

as people sometimes think. And you

don't need to wrap your yarn differently

to try and get rid of the slants in

the stitches.

So the next time

you go to your LYS, take a good look

at the wool yarns. Appreciate the

differences and knit away, now that

you know the appearance of your knitting

is exactly what it should be.